Use of Laminated Glass in Glass Railing Systems

Glass Informational Bulletin - GANA 09-0417

Introduction

Glass railing systems are used in a variety of residential and commercial settings for safety and the beauty

glass adds to a structure. Laminated glass is the ideal glazing material for this application and offers a

variety of design options. The interlayer can be clear, tinted, or custom printed. The glass can be clear,

tinted or decorative; flat or curved; fully supported on 1, 2, 3, or 4 edges; or minimally supported with

bolts and/or clamps. Laminated glass offers a benefit over monolithic tempered glass when used in

railings; if breakage occurs, glass particles tend to adhere to the laminate interlayer increasing the

likelihood of glass retention in the system.

Interior glass railings create an open feeling on the inside of a large space and enhance visibility and

daylighting. These railing systems may be used in spaces such as, but not limited to, shopping centers,

hotels, office buildings, restaurants and hospitals. Laminated glass railing systems can also be installed in

exterior applications, such as balconies in apartments, hotels, and condominiums. Laminated glass

provides improved resistance to glass fallout in the event of breakage. If the laminate edge is not covered,

additional consideration should be given to the interlayer type and glazing system design.

Laminated glass railing systems provide a clear barrier in many sports venues around the world. While a

top rail is still required by code, in some instances the metal top cap and handrail have been eliminated,

with approval of the building official, to afford spectators an unobstructed view onto the playing field.

This is discussed in further detail in the Building Code Requirements section below with regards to code

adherence

Definitions

Handrail : According to the IBC 2015, a horizontal or sloping rail intended for grasping by the hand for guidance or support.

Guardrail : According to ASTM E2353 Section 3.2.3, a protective railing system around the outer edges of locations of an accessible roof, balcony, landing, platform or ramp designed to minimize the probability of an accidental fall from the walking surface.

Guard

: According to the IBC 2015, a building component or

system of building components located at or near the open sides of

elevated walking surfaces that minimizes the possibility of a fall

from the walking surface to a lower level.

Baluster:

a vertical support piece, such as a lite of glass.

Balustrade

:

a railing supported by balusters.

Infill Panel

: the material that occupies the space between

supporting structural members of the system, and functions as the

guard in the system.

Glass Selection

ASTM C1172 Standard Specification for Laminated Architectural Flat Glass is the industry specification for laminated glass. ASTM C1048 - Standard Specification for Heat-Strengthened and Fully Tempered Flat Glass is the industry specification for heat-strengthened and tempered glass. ASTM C1048 also contains vital information about the fabrication of holes and/or notches.

Additionally,

two ASTM standards and one Canadian Standards Association (CSA)

standard address testing, specification, and design of glass

railings. These are:

- ASTM

E2353 Standard

Test Methods for Performance of Glass in Permanent Glass Railing

Systems, Guards, and Balustrades

- ASTM

E2358 Standard

Specification for the Performance of Glass in Permanent Glass Railing

Systems, Guards, and Balustrades

- CSA

A500 Guard Standard

Building Code

Requirements

The 2015 International Building Code (IBC) makes specific reference to glass railings in Section 2407 of the code. The code requires the use of laminated glass with very few exceptions.

The

main points of section 2407 of the 2015 IBC are:

- Laminated

glass must be used in handrails, guardrails or

guards.

- Glass

types must be fully tempered laminated or heat-strengthened

laminated.

- Laminate

must comply with CPSC 16 CFR 1201 Cat II or ANSI Z97.1-2015 Class

A

- Minimum

nominal thickness must be 1/4

in.

- Single

fully tempered glass is permitted where there is no walking surface

beneath the system or where the surface is permanently protected

from the risk of falling

glass.

- Handrail

or guard section must be supported by a minimum of three glass

balusters, or shall be otherwise supported to remain in place should

one baluster panel

fail.

- The

panels and their support systems should be designed to withstand the

loads as specified by the code. A design factor of 4 must be used

in designing the

glass.*

- Top

rail is not required if the laminated glass is comprised of two or

more glass lites having equal thickness and only then if the system

receives approval from the building

official.

- In

windborne debris regions, in-fill glass and glass balusters must be

laminated and comply with safety glazing

standards.

- In

windborne debris regions, if the glass is supporting a top rail, the

top rail must stay in place after impact

testing.

- Glazing

materials may not be installed as handrails or guards in parking

garages except in pedestrian

areas.

The 2015 IBC represents a major change in the use of glass in railing

systems. Prior to the 2015 code, the designer could use either

monolithic tempered or laminated glass in most railing applications.

As states adopt the 2015 IBC, the use of monolithic tempered glass

will be restricted, and will be replaced by a heat-strengthened or

tempered laminated glass alternative. The adoption process is often

slow at the state level. Since older versions of the code may govern

the code approval process, designers and specifier are advised to

consider the risks associated with glass breakage and specify

laminated glass to conform to best industry

practices.

*The

design factor is used to reduce a material’s limiting stress to an

allowable stress in design.

Glass

Railing Performance Standards

(derived

from ASTM E2358)

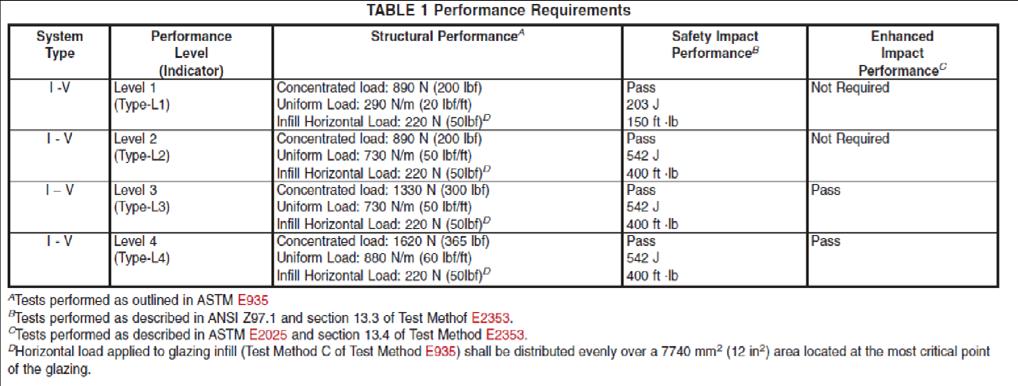

Glass railing system testing is done according to ASTM E2353 Standard Test Methods for Performance of Glass in Permanent Glass Railing Systems, Guards & Balustrades . The standard evaluates static strength, impact resistance, and post-break retention. Railing systems are specified according to ASTM E2358, Standard Specification for the Performance of Glass in Permanent Glass Railing Systems, Guards, and Balustrades . These systems include glazing infill, as well as structural glass railing types. The four levels of performance are shown in Table 1. Post-impact classifications per ASTM E2358 are shown below.

Reprinted, with permission, from ASTM E2358-04(2010) Standard Specification for the Performance of Glass in Permanent Glass Railing Systems, Guards, and Balustrades, copyright ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA 19428, www.astm.org .

Post-impact classifications of laminated glass railings from ASTM

E2353 are shown below. It is anticipated that future model building

code changes will take into account the post-impact classification

as a way of avoiding the requirement to get building official

approval mentioned in point 8 above. A post-impact classification of

1 or 2 must be met to prevent falling glass as well as to increase

protection of building occupants above ground level from falling

through an unprotected opening. For Classification 2, the load

that must be retained after breakage has yet to be

determined.

Post-Impact Classification

- Glazing

unbroken

- Glazing broken and

retained

- Glazing broken and not

retained

Laminated Glass

Quality

Unlike monolithic tempered glass, edge quality with laminated glass must be clearly specified to the glass fabricator. Issues such as edge misalignment and protruding interlayer may impact the aesthetics and safety of the glass edge.

ASTM C1172 Section 8.5.1 shows standard tolerances for laminated

glass including misalignment. Tighter tolerances may be required for

exposed edge applications. This concern is addressed in Section

8.5.3 where it states, “For some laminated applications such as point supported glass and balustrades, where the edges of the laminate are exposed, tighter length and width tolerances may be requested by the customer. Consult the supplier to determine their capabilities.”

Glazing System

Considerations

When a system is wet glazed, it is important to verify compatibility of the caulk, grout, blocks, and sealant used in contact with the laminate interlayer. This is especially important in exterior applications where moisture and expansion rates can impact the system. Traditional methods of setting monolithic glass in railings such as cement-based grouts may be incompatible with laminated glass. Polyurethane or epoxy type sealants may be suitable alternatives. Dry-glaze methods have shown to be compatible with laminated glass systems. Bolted or clamped systems must be designed and installed properly to avoid over-stressing the glass around the points of contact. Consult with the fabricator and component suppliers (i.e. interlayer manufacturers, sealant suppliers, etc.) for questions surrounding compatibility.

For

additional information on laminated glazing materials consult the

GANA Laminated

Glazing Reference Manual

and

the GANA website: www.glasswebsite.com

.

The

Glass Association of North America (GANA) has produced this Glass

Informational Bulletin solely to provide information regarding the

use of laminated glass in glass railing systems. This bulletin makes

no attempt to provide all information or considerations in the use of

laminated glass. The user of this Bulletin has the responsibility to

ensure their awareness of the use of laminated glass in glass railing

systems. GANA disclaims any responsibility for any specific results

related to the use of this Bulletin, for any errors or omissions

contained in the Bulletin, and for any liability for loss or damage

of any kind arising out of the use of this Bulletin.

This

bulletin was developed by the GANA Laminating Division and by the

membership and the GANA Board of Directors. The original version of

the document as approved and published in March 2011. This version

was re-published in May 2013 and April 2017.